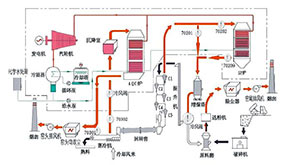

水泥厂低温余热系统(Cement Waste Heat Recovery System) 水泥厂余热发电流程图(Cement cogeneration flowchart)

目前,国内炼钢、有色金属、焦化、重化工,暂时没有强制余热利用规定;只有干法水泥窑国家出台了法规。统计证明,低温余热发电系统为水泥吨成本节省20元,产生良好的经济和社会效益,向横向行业推广是必然趋势。

公司结合窑生产线地理位置、气候条件(如高原、高寒、潮湿多雨)均有成熟方案。

针对国家确定市政管网污泥由水泥厂处置的指导思想,本公司结合水泥窑炉特点,按不同方案,采用预热器、原料磨为投料点,提供一揽子方案,既彰显水泥企业社会责任又为企业的转型提供新思路。

目前在一下行业均有成熟方案:

1、水泥干法窑余热发电

2、遂道窑制砖余热发电

3、干熄焦余热发电

4、铁合金铬矿冶炼余热发电

Till now, there have not mandatory requirements to use waste heat in the steel making, nonferrous metals, coking, heavy chemical industries except the processing cement kiln. The state published the laws and regu-lations. About 1500 dry process production lines, there have 1200 production lines to be installed the co-generation during the 5 years. The statistics prove that the Cogeneration save 20 yuan per one ton cement. It makes good economic and social benefits, it is inevitable to expand the cogeneration in the cross industry.

Company considered kiln production line location, climatic conditions. Such as:altitude, GaoHan, Wet rain areas, we have the complete scheme.

Based on the state theory that the cement factory dispose of the waste sludge from the municipal pipe network, our company furnace advantages: According to different options, use preheating, mill raw material etc. we provide all kinds of solutions to help the cement factory transformation and reflect social responsi-bility.

Currently in the industry have a mature program:

1、cement dry kiln waste heat power generation

2、brick tunnel kiln waste heat power generation

3、CDQ waste heat power generation

4、chromium iron alloy smelting waste heat power generation